PULTRUSION MACHINES & PULTRUSION MOULDS

About Us

Professional FRP pultrusion mold & pultrusion machine suppiler from China

XJL is a professional FRP pultrusion mold & pultrusion machine supplier in China. We provide a one-stop solution for both pultrusion molds and pultrusion machinery for customers in FRP pultrusion field. We offer a complete turn-key tooling package to fiberglass pultrusion pultrusion die Our service includes:

1) Pultrusion mold, mandrel, preformer design and manufacture

2) Pultrusion machine and accessories

3) Roving guide plate design and manufacture

4) Mat, roving and pre-former

We offer a range of pultrusion molds, including molds for FRP cable trays, handrails, and for FRP tubes. Contact us today to schedule a free consultation.

Got a question about pultrusion? Let's chat about it.

Phone: +86 153-5059-2434

Email: info@amprtech.com

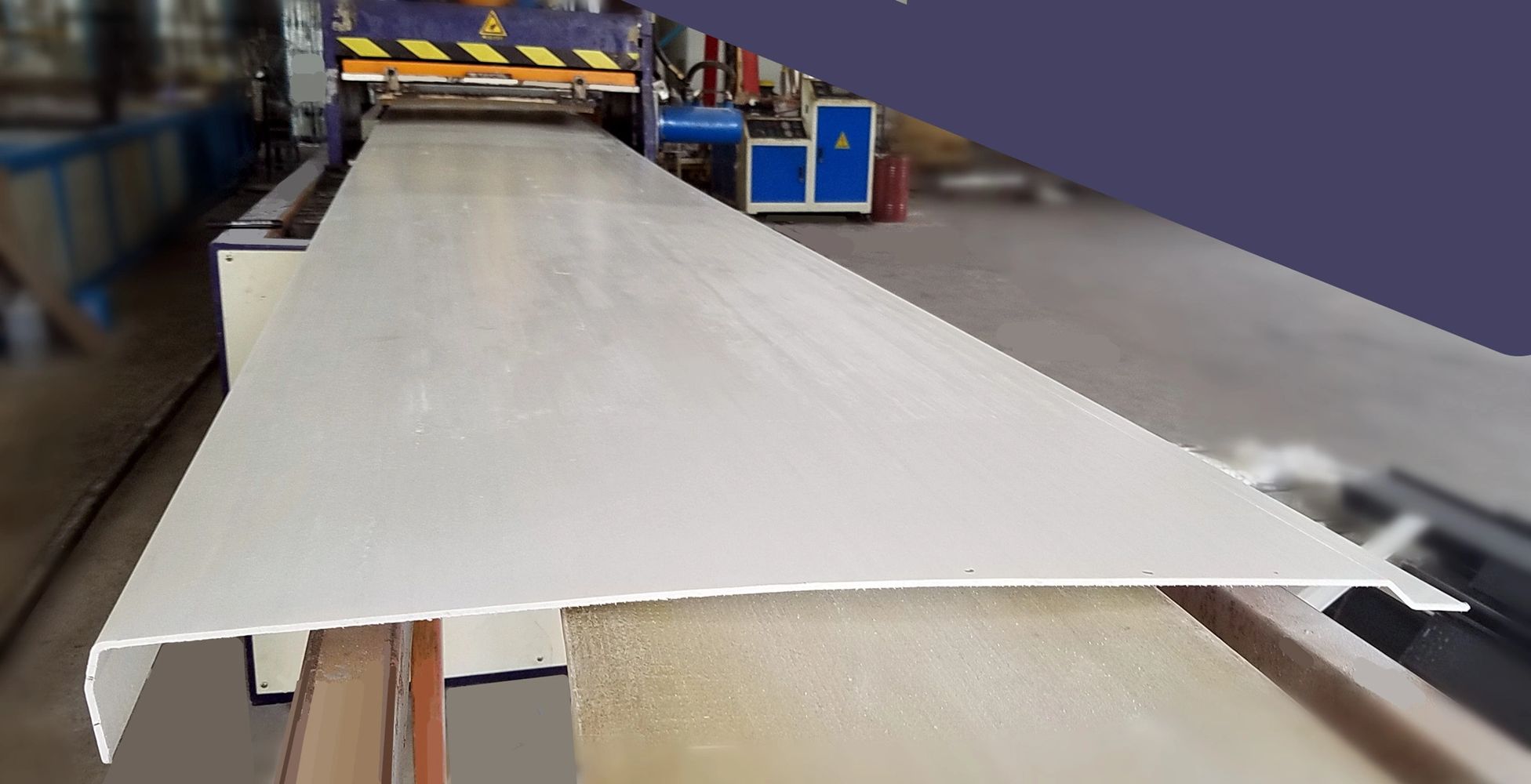

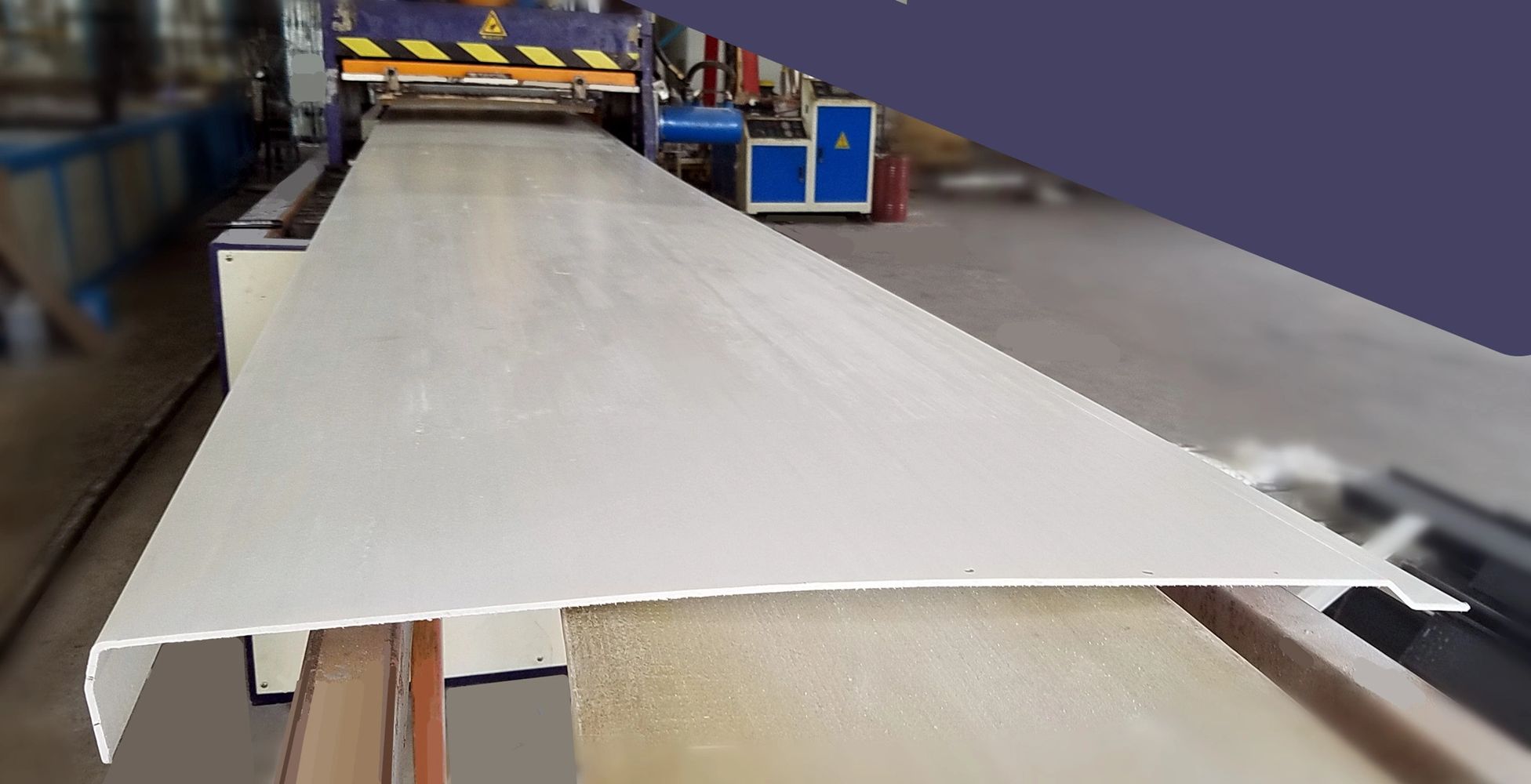

PULTRUSION MOLDS

WHY XJL PULTRUSION MOULDS

- Worldwide shipping by air, by sea or by sea

- 50,000m mold life guarantee & 100% guarantee

- One-stop solution for pultrusion

- 24-hour service technology support

- Customizable pultrusion molds pultrusion die fiberglass pultrusion

- Complete and strict quality controlling system

- Precise measuring devices

- The cavity size of each pultrusion mold will be measured automatically by a CMM (coordinate measuring machine), the precision is 0.001mm.

- Besides molds of regular FRP profiles (beams, channels, tubes and rods etc), we also offer pultrusion dies for custom profiles based on drawings.

- As a professional FRP pultrusion mold manufacturer in China, we provide a one-stop solution for customers - no matter molds, preformers, material (mats, glass fiber roving, mold release, additives, etc).

PULTRUSION MOLD MANUFACTURE PROCESS

Pultrusion mold manufacture process

- The production process for FRP pultrusion molds starts with the design phase, which involves creating detailed engineering drawings and specifications that align with the desired product dimensions and material characteristics. .

- Next, high-quality mold steel are selected for the mold construction to withstand the rigors of the pultrusion process.

- Once the materials are prepared, the machining phase begins, where components are cut, shaped using CNC smiling and grinding machines for accuracy,

- Cavity Polishing - this Is the most important step to keep the cavity smooth for the pultrusion tooling

- After polishing, the mold undergoes heat treatment to enhance durability and reduce friction during the pultrusion process.

- Finali assembly, assembled step is also important for accuracy of pultrusion mold.

- Finally, rigorous quality control checks are conducted to ensure that the molds meet all specifications before being shipping to customers.

- Mold testing if needed.

FRP PULTRUSION LINES

FRP Pultrusion Machine

- 3-30T hydraulic / caterpillar pultrusion machine - pultrusion machinery

- Optional production line components

- 3 series of pultrusion machine meet various needs.

FRP Winding Machine

FRP winding machine is a specialized equipment manufacturing through filament winding technique of cylindrical and spherical FRP profiles, such as pipes, tanks, and pressure vessels. There are 2 series of products to meet customer's needs.

FRP/Basalt Rebar Machine

FRP (Fiber Reinforced Plastic) and basalt rebar machines are specialized production lines to manufacture reinforcement bars using composite materials.

FAQ

If you can't find the answers to your questions below, please email or call us directly, tel / whatsapp +86 15350592434, info@amprtech.com

Yes, we are located in China, and we can make the shipment to you directly by air, by train, or by sea.

The following mold steel and finish are mostly used for our pultrusion mould: 40Cr with hard Chrome plating, 40Cr with Nitride finishing, P20 with hard Chrome plating, Cr12 highly polished, 38CrMoAl with Nitride finishing, The type of finishing of mold cavity depends on the type of mold steel, the resin system used in the pultrusion and also the mold life expected. Our experts will recommend it when ordering.

Yes, we provide a full set of drawing for the pultrusion mold /preformer for you to confirm every detail of the mold, including the parting line, structure, fixing, ...

Preformer can be ordered separately when ordering molds.

Normally it takes 25 to 35 days to manufacture one set of pultrusion mold, but the time will probably be longer for the manufacturing of more pieces or a larger size of mold.

1. Open the mold carefully after cooling down.

2. Use soft metal (like copper bar or copper strips) to clean the mold to avoid any damaging of mold cavity.

3. Wipe the mold with soft cloth.

4. Close the mold carefully.

The mandrel must be kept straight when stored; hanging it up is the best way to keep it from deforming.

Avoid moisture and dust when store.

Yes, we will test the molds before shipping them to you.

Yes, we provide 24-hour online service to make sure the mold and machine are working properly. We also have on-site training.

Hear From Happy Clients

CONTACT US

Our pultrusion expert is ready to give you support.

We love our customers, if any questions for pultrusion machinery pultrusion mold pultrusion die , please feel free to call or email us.

AIMIPAER FRP PULTRUSION TECH -

Address: Intersection of South 2nd Ring Road and 107 National road, High-tech Zone, Xinxiang City, Henan, China Branch: #1101 Hengtai international building, #138-2, Huaian road, Yuhua district, Shijiazhuang, Hebei, China

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.

.jpg/:/cr=t:0%25,l:47.14%25,w:38.67%25,h:99.99%25/rs=w:365,h:365,cg:true,m)